Architects: Tomoaki Uno Photography: Nathanael Bennett Construction Period: 2024 Location: Mikawa Bay, Japan

The recent health boom has increased the number of people who prefer to eat brown rice. However, because of the taste and texture, there are not many who choose to eat it every day. There is an enzymatic brown rice recipe which is a tasty and nutritious way to eat brown rice as part of one’s daily diet. The only ingredients are brown rice, azuki beans, and sun-dried salt, but the cooking process is quite time-consuming to make it every day. The owner of this company is the first person in Japan to make it possible to cook brown rice in a rice cooker, just as you would cook white rice. She and her partner, who is an engineer, succeeded in commercializing the product several years ago, and the company has been making steady progress ever since.

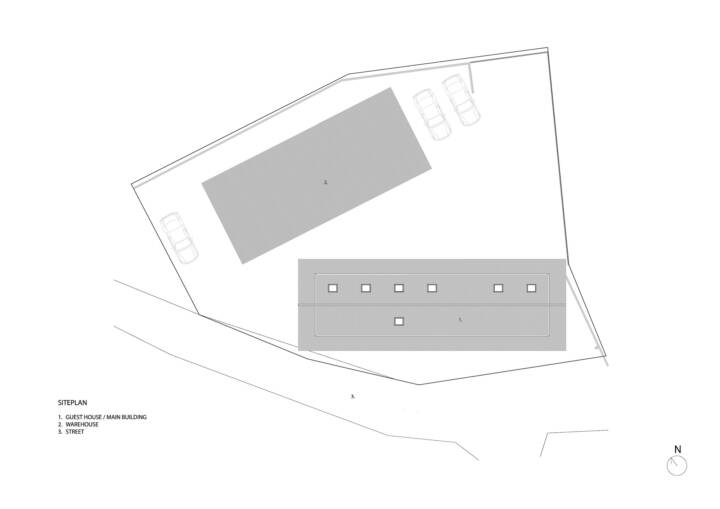

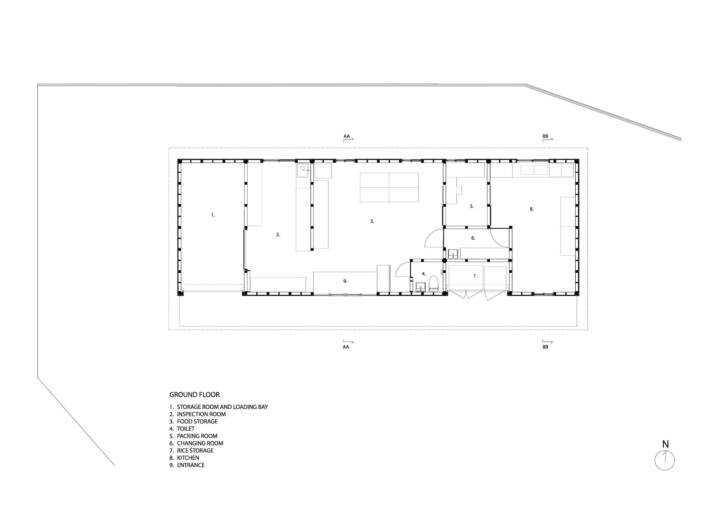

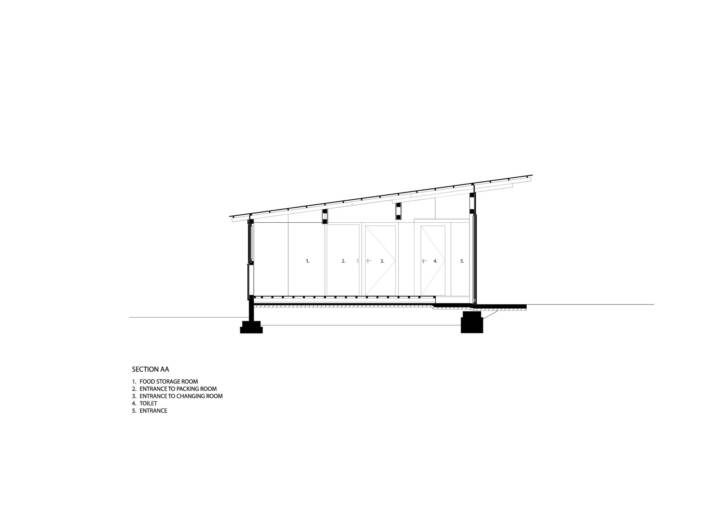

The site is located in front of Terabe Beach near the centre of Mikawa Bay. The land, with an unobstructed view of Mikawa Bay, was the site of a beach house that was once run by the owner’s parents. It had been renovated to house a showroom and food-tasting booth and was open for business. However, it had become too cramped and not in keeping with the corporate image, and the decision was made to rebuild it. The company decided to renovate the existing showroom and allow for tasting sessions.

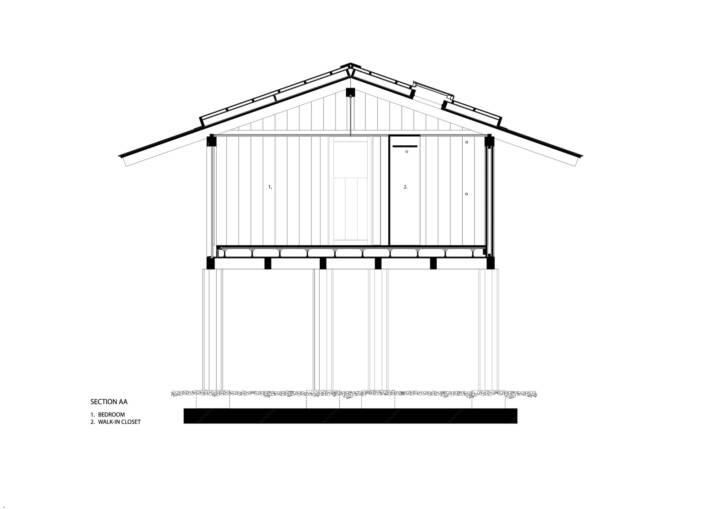

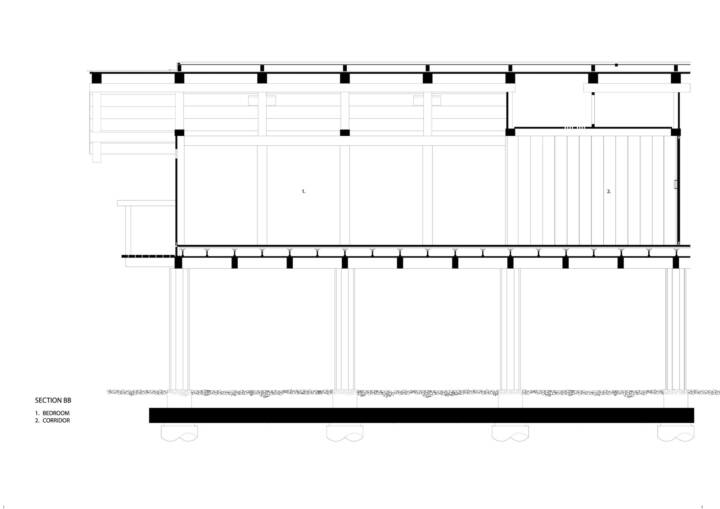

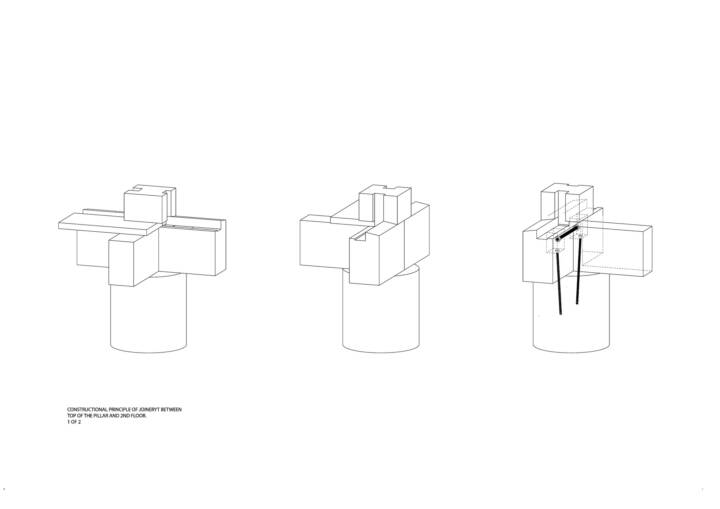

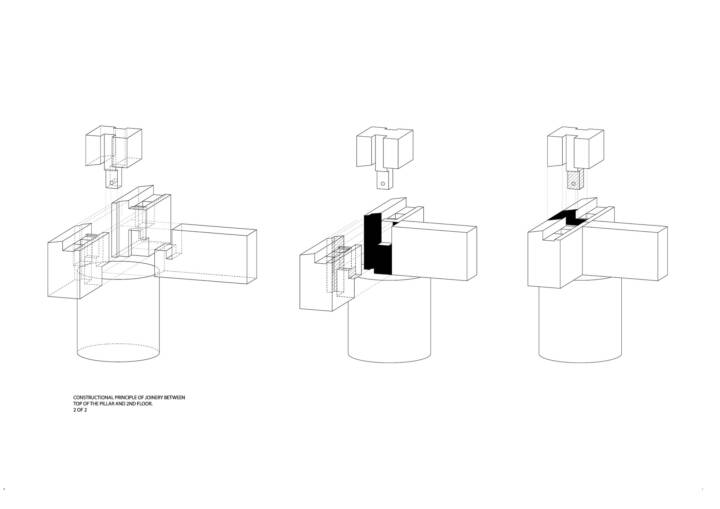

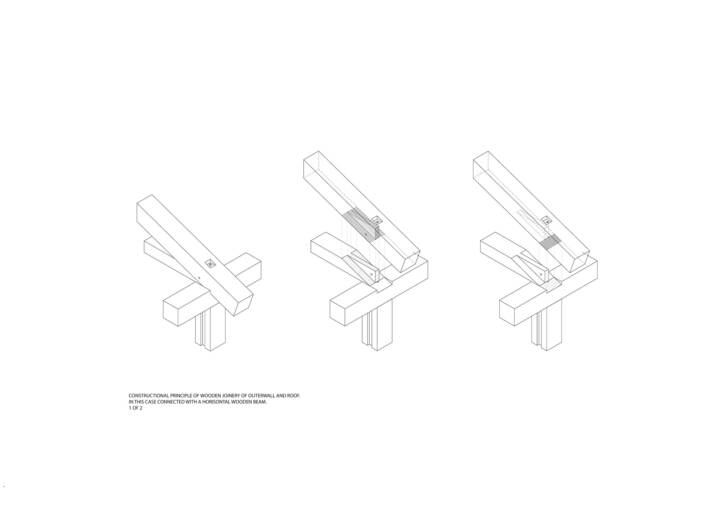

As a tourist resort crowded with bathers in the summer, they wanted a building that was calm and inviting, and that would make the most of the scenery. This required a bold proposal. Based on the client’s wishes and the company’s image, it was decided that the building would be made from wood. At that point, there was no real evidence of a construction method or structure, but I proposed that the entire ground floor should be made of pilotis. When the clients saw this, they said they wanted to use the area around the pilotis as a parking area as well. This would make it impossible to use point foundations, etc. Attempts to calculate the marginal bearing capacity were unavoidably shot down due to the sheer bulk of the structure and the budget. After nearly half a year of considering various structures and construction methods, we arrived at the most modern construction method, in which the pillars are rigidly connected to the solid foundation using steel posts or ‘Home Connectors’, and the upper building is then placed on top of the pillars. After that, there was considerable effort to determine the most reasonable yet beautiful dimensions, such as the pitch and thickness of the columns.

Read MoreCloseWe worked the uneven logs into regular 33cm circular columns as our first task. We could have machine-cut the logs, but we chose to shape them there on the site. We started using traditional ‘yarikana’ or spear planes, but we later moved to using electric planers to speed up the process. So far, everything has gone according to plan. However, when I saw the 32 logs, I felt a little bit unsatisfied. Having spent many years looking at old temples and shrines, ‘Mukuri’ was still something I longed for. After much work, the round pillars were laid out on the site and all the pillars had that ‘mukuri’ quality. I still have fond memories of the smiles on everyone’s faces when we had finished everything.

After a brief moment of respite, the carpenters soon informed us that it would be difficult to join the foundations and columns as had previously been planned. The method used was to rigidly join the foundation and columns with anchoring hardware (home connectors). As they had some experience with this method before, they were a little bit tentative about it. According to them, the anchors needed to be cast with incomparably greater precision than had been needed in the past. After much thought, they came up with a brilliant idea that went down remarkably well. Instead of placing the anchors into the concrete, they attached them first to the round columns and then later cast them in the concrete foundation.

Here are a few examples of changes made at the suggestions of the craftsmen:

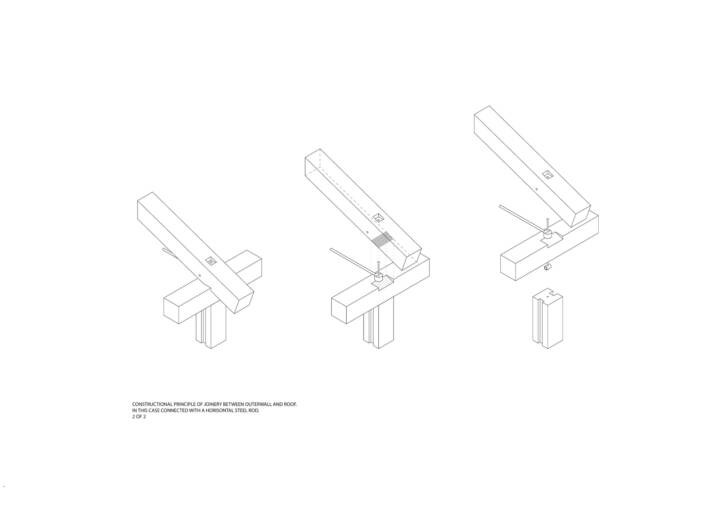

One was a point about the strength of the staircase landing. I thought that if the landing was fixed to the surrounding beams, there would be no problem. However, it was pointed out that this would be too weak. The final idea was to fix it to the floor beams on the second floor and take it out, as shown in the picture. The other was the delivery of the balcony floor. For the flooring material, it was decided to use Australian cypress for weather resistance. However, it was pointed out that this timber was not dry enough and was likely to warp after installation, and that the floor was also not rigid enough. They suggested that each piece of the flooring be supported by several horizontal round bars running through it. This would kill two birds with one stone, as they would hold each other to prevent warping and also ensure rigidity. In this way, the experience and wisdom of the craftsmen were utilized everywhere, increasing the degree of architectural perfection. It should be noted that most of the suggestions made by these craftsmen are used in invisible parts of the building. This is the essence of craftsmanship, and I always admire it.

The reason why I became involved in construction is simple. I wanted to prove to myself that I could do it. When working with construction companies, I often had to adapt to their circumstances, and often ended up with compromises and unexplained problems. To solve this, as a result, the only option left was to become a building contractor. When I started, I was very determined to build as closely as possible to the blueprints, partly because I didn’t have a very good team of craftsmen. Nevertheless, I had much more freedom as an architect than before. For a while, I was absorbed in the joy and pleasure of it, but I also realized that I was slowly waking up from that dream. About 10 years after I started working as a contractor, I had a team of craftsmen, and I was able to ask their opinions and work with them more than before. It was around that time that I discovered new joys and pleasures. It was not a matter of following a blueprint, but of working with the craftspeople at that moment to find the best possible outcome. From that time onwards, I realized that the site was like a living organism, growing beyond my imagination. That discovery and realization made me even more fascinated by architecture. Now, for me, the beginning of a site is the beginning of a new design. I cook my desktop ideas in the pot of the construction site. I always go there with this in mind.

*Home connector, a method of rigidly joining using special anchor bolts fixed with epoxy resin.

Text provided by the architect.